Natural Slate

Timeless elegance and unmatched longevity.

Timeless elegance and unmatched longevity.

Rustic warmth with natural insulation.

Slate & shake looks, modern performance.

Architectural shingles with slate-like appeal.

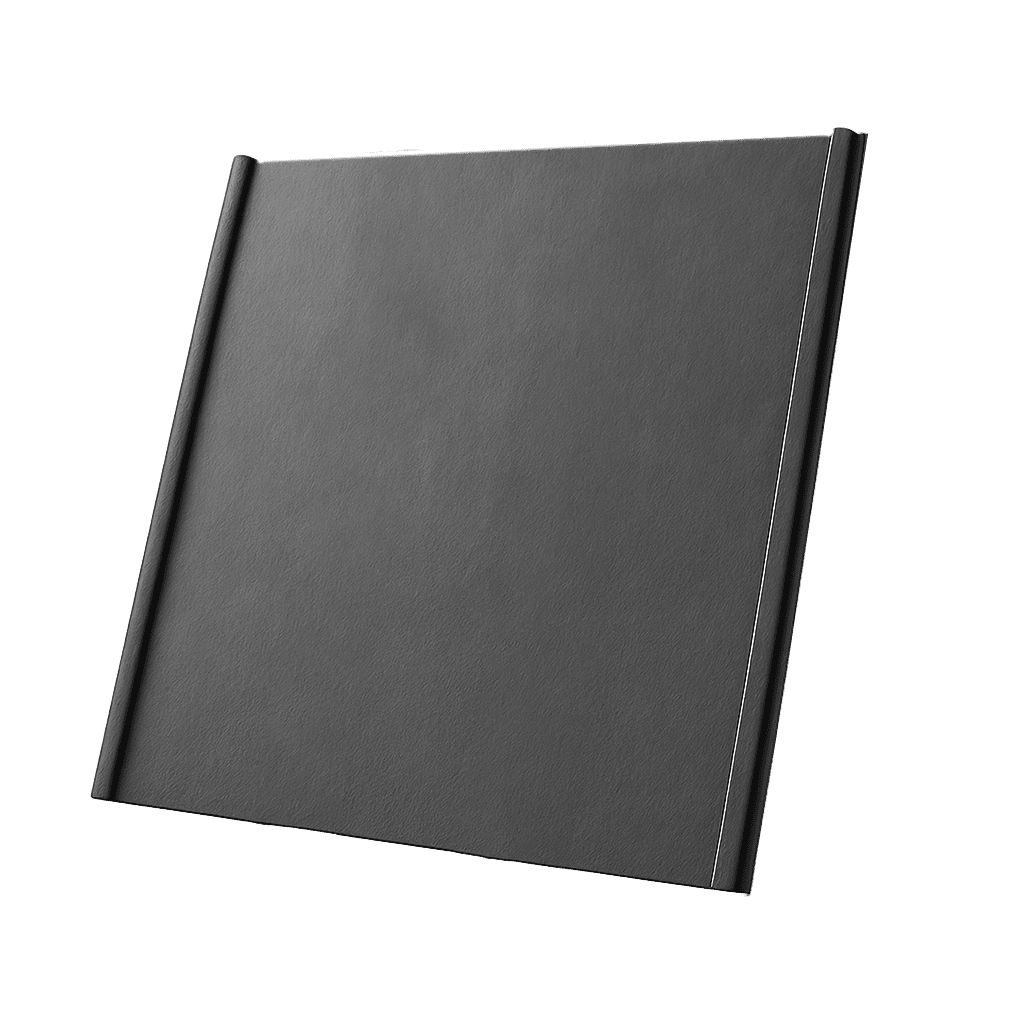

Energy-efficient, modern, and long-lasting.

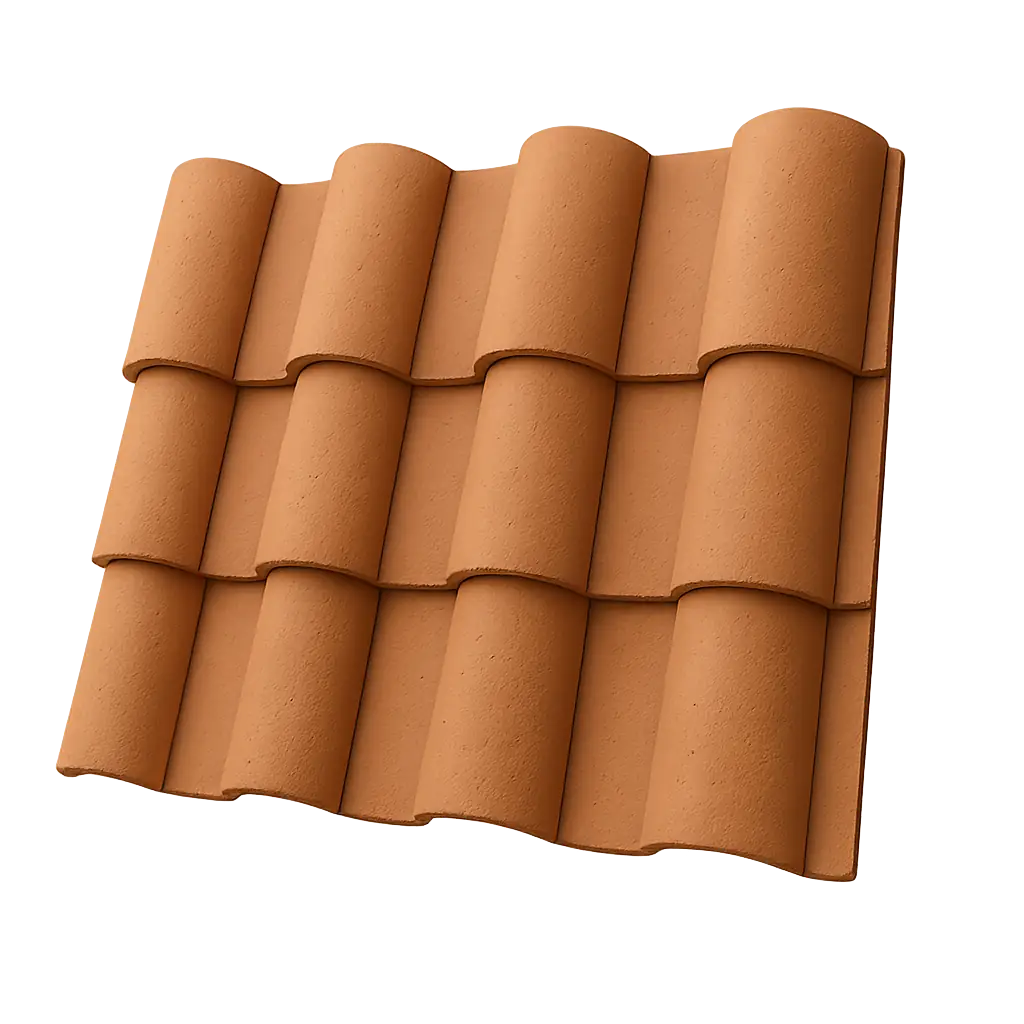

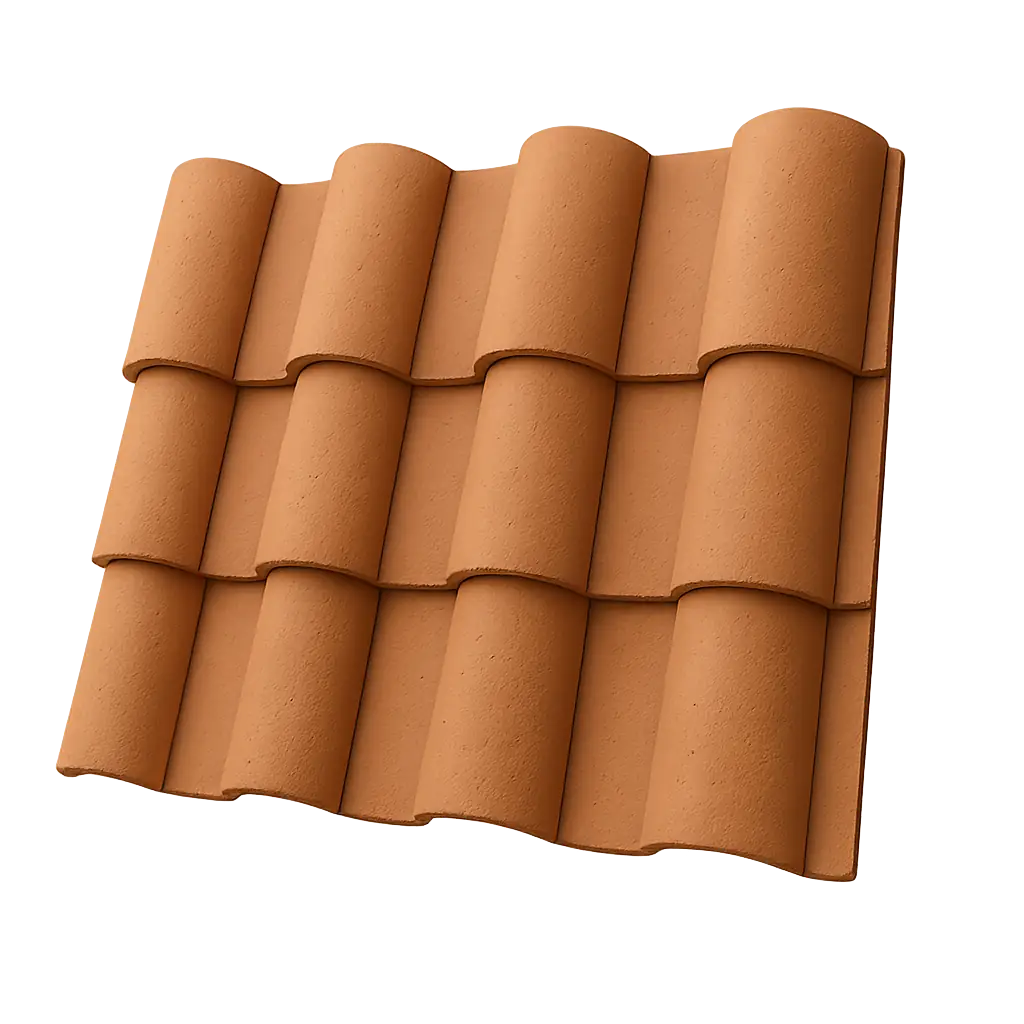

Mediterranean beauty, natural fire resistance.

Lightweight durability with classic charm.

Wood shake appearance, no rot or warping.

The gold standard for low-slope protection.

Eco-friendly composites with authentic detail

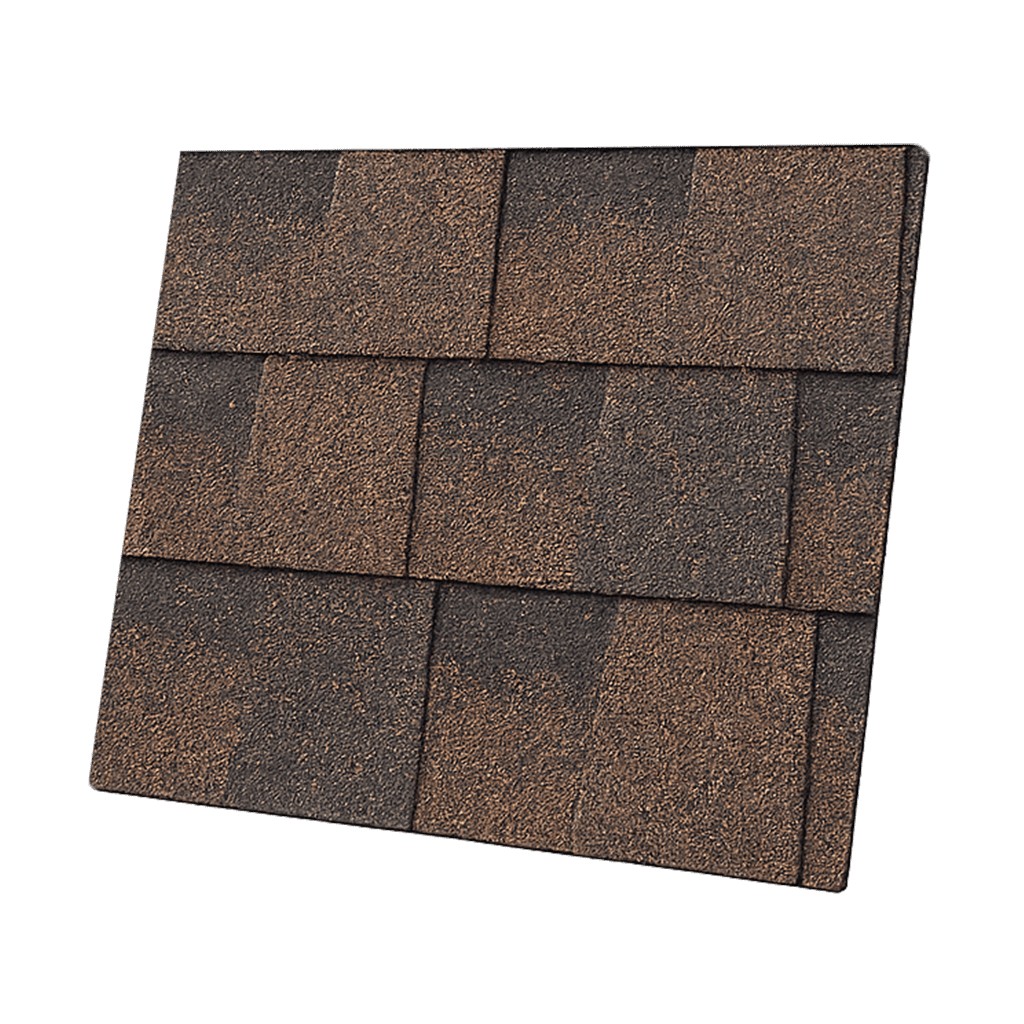

Classic layered look, durable protection.

Share

Share

Homeowners assume premium roofing materials guarantee premium results. Pay more, get more life. Simple math.

But inspection after inspection reveals the same patterns: expensive roofs failing decades before they should. And the cause is rarely the material itself.

The shingles, tiles, and shakes get blamed. Homeowners think they bought a bad product or got unlucky. But when you pull back the layers and look at what actually went wrong, the patterns become clear.

Most premature roof failures trace back to the same handful of causes. None of them appear on a manufacturer’s spec sheet. All of them are preventable.

A roofing material has a potential lifespan. Call it what the product could achieve under good conditions with proper installation and maintenance.

Then there’s actual lifespan. What the roof delivers in the real world on your specific home.

The gap between these two numbers is where money gets wasted and homeowners get frustrated.

A natural slate roof can last 100 years. But if the flashings fail at year 30 and water infiltrates the deck for five years before anyone notices, that slate roof becomes a tear-off. The slate itself might still be fine. The system failed.

A synthetic shake roof rated for 50 years can start curling at year 15 if the attic beneath it runs 140 degrees every summer due to blocked ventilation.

A cedar shake roof can rot in 20 years on one house and last 35 on the house next door, installed the same year by the same crew. The difference? One house has heavy tree coverage holding moisture against the wood. The other sits in full sun.

Material matters. But material alone doesn’t determine outcomes.

After years of climbing ladders, walking roof decks, and crawling through attics, certain failure patterns show up again and again. Here’s what actually kills roofs early.

This is the single biggest factor in premature roof aging. It’s also the least visible to homeowners and the most overlooked by budget-focused installers.

Your attic needs to breathe. Hot air needs to escape in summer. Moisture needs to vent in winter. When this airflow gets blocked or was never adequate to begin with, problems compound.

What poor ventilation does to roofs:

In summer, trapped heat in an unventilated attic can reach 150 degrees or higher. That heat radiates into the roof deck and roofing material from below. Asphalt shingles cook from both sides. Synthetic materials experience accelerated UV stress. Even slate and tile roofs suffer as the extreme heat degrades underlayments.

In winter, warm air from the living space rises into the attic. If it can’t escape, it condenses on cold surfaces. This moisture saturates insulation, rots deck sheathing, and creates conditions for mold and ice dams.

Common ventilation problems found during inspections:

A roof inspection that doesn’t include attic access misses half the story. The problems underneath often matter more than what’s visible from the street.

Flashings are the metal pieces that seal transitions. Chimneys, valleys, skylights, vent pipes, walls meeting roof planes. Anywhere water might find a path, flashing is supposed to stop it.

Flashings fail more often than roofing materials. And when they fail, water gets in.

Why flashings fail:

Chimney flashings are the most frequent failure point. The intersection of a vertical masonry structure and a sloped roof surface is complex. Counter-flashings need to be set into mortar joints, not just surface-mounted with sealant. Step flashings need to weave with each course of shingles. Many installers take shortcuts here.

When homeowners report a “roof leak,” it’s flashing failure more often than shingle or tile failure.

Every roofing manufacturer publishes installation specifications. Follow these instructions and the warranty applies. Deviate from them and the warranty is void, even if the homeowner never knows it.

Inspections reveal installation errors on a majority of roofs. Some errors are minor. Some guarantee early failure.

Common installation problems:

The challenge for homeowners: you can’t see most of these errors after installation. The roof looks fine. It might even perform fine for years. But the problems are built in, waiting to surface.

This is why installer selection matters as much as material selection. Material lifespan means nothing if installation cuts that life short.

No roof is maintenance-free. Some materials need more attention than others, but all roofing systems benefit from periodic inspection and care.

What maintenance neglect looks like:

Cedar shake and natural slate require the most active maintenance. But even “low maintenance” synthetic and asphalt roofs need periodic attention.

An inspection every two to three years catches small problems before they become expensive ones.

The roof deck is the plywood or board sheathing that roofing materials attach to. If the deck fails, it doesn’t matter how good your shingles are.

Deck problems found during inspections:

Reputable contractors include deck inspection and address any damage before installing new roofing. Less reputable ones cover it up and move on.

This is where “hidden costs” legitimately appear. But honest contractors communicate this upfront, explaining what they might find and how they’ll handle it, before work begins.

Building codes typically allow two layers of roofing before tear-off is required. Some homeowners, hoping to save on removal costs, opt to roof over existing materials.

This is almost always a mistake.

Why layovers fail:

Inspections of layover roofs consistently find problems. The money “saved” by not tearing off rarely holds up when you calculate the shortened lifespan and compounded future removal costs.

A meaningful roof inspection goes beyond walking the surface and looking for obvious damage. Here’s what a thorough evaluation includes.

Exterior evaluation:

Attic evaluation:

Documentation:

A two-minute walk-around with a clipboard isn’t an inspection. It’s a formality before a sales pitch.

Understanding why roofs fail early leads directly to preventing those failures.

Before installation:

After installation:

When problems appear:

Inspection findings shape decisions. A roof at 80% of its useful life needs different treatment than one at 20%.

Sometimes the answer is targeted repair. Sometimes it’s planning for replacement in three to five years. Sometimes it’s immediate action.

But you can’t make good decisions without accurate information about current condition.

If your roof is aging, showing wear, or you’re simply uncertain about its status, a professional evaluation provides the clarity you need. Not a sales pitch. Not pressure. Just honest assessment of what’s happening and what your options are.

The best time to understand your roof’s condition is before problems force your hand.

Wolf Development provides thorough roof evaluations for homeowners across Chicago’s North Shore and western suburbs. Our inspections cover materials, flashings, ventilation, and deck condition to give you complete information about your roof’s current state and remaining useful life.

Timeless elegance and unmatched longevity.

Rustic warmth with natural insulation.

Slate & shake looks, modern performance.

Architectural shingles with slate-like appeal.

Energy-efficient, modern, and long-lasting.

Mediterranean beauty, natural fire resistance.

Lightweight durability with classic charm.

Wood shake appearance, no rot or warping.

The gold standard for low-slope protection.

Eco-friendly composites with authentic detail

Classic layered look, durable protection.